Arc Flash Labels

Are You Compliant?

Arc Flash Analysis = Safety

An arc flash analysis is a complete engineering study of the equipment that your electrical distribution system consists of. The study encompasses voltages, equipment ratings based on manufacturers specifications and adjustable settings of protection devices. When all the necessary data collection is completed, calculations are completed by a P. E. that establishes the requirements of an electrical safety program.

During the study numbers will be crunched, a hazard report generated, accurate one-line drawings developed, PPE requirements established, and labels placed on equipment.

What determines your electrical safety program: generic labels or a complete engineering study? NFPA 70E has established generic guidelines for arc flash PPE requirements. These guidelines have many footnotes to consider, compensation for human error exists (i.e., a bolted vs. hinged panel cover). Yet, bolts and hinges do not change the incident energy that exists at a specific piece of equipment.

Generically or incorrectly labeling equipment can result in injury and liability. Only a complete engineering study based on accurate data collection can establish a reliable electrical safety program.

Thermal Technologies provides the answer!! Accurate data collection conducted during infrared inspections is the most efficient choice in developing an arc flash safety program. Engineering based on system design and equipment settings proves to be the only true alternative for an accurate and reliable electrical safety program.

GENERIC LABELS vs. THE FACTS

YOUR CHOICE = SAFETY

What is needed to implement an accurate

Arc Flash Hazard Analysis?

|

Develop accurate one-lines that help workers identify equipment voltage levels, sources, tie breakers, and various system configurations that impact hazard calculations. These will also be used for planning purposes to determine back feeds and energized sources. “NFPA 70E Article 120.1(F)(1), 205.2” |

Field data collection of electrical equipment nameplate parameters. These parameters in conjunction with the EasyPower® software library provide a comprehensive model and database of the electrical system to perform all types of analysis. |

|

Perform short circuit and equipment duty calculations to ensure all equipment is properly rated to withstand and interrupt the available short circuit current. Improperly rated equipment can result in catastrophic failure. “NFPA 70E Article 400.5, 400.6” |

Perform protective device coordination (circuit breakers, fuses, protective relays, etc.) to ensure that each device will operate properly on the available bolted and arcing short circuit current. Proper protective device selection and coordination (settings) will reduce arc flash hazards and worker exposure, increasing plant reliability. “NFPA 70E Article 410.9” |

|

Perform arc flash hazard calculations based on IEEE-1584 or NFPA 70E formulas and guidelines. Worst-case calculations should be determined for all equipment. “NFPA 70E Article 130.1, 130.3” |

Create labels from EasyPower to provide Article 400.11 compliance and ensure worst-case hazards are posted and visible for all equipment. Article 400.11 EasyPower® software will create your one-line diagrams, document the electrical system parameters, accurately perform the required 70E calculations, and evaluate options to reduce hazards and risk to personnel. EasyPower’s detailed analysis can prevent the mistakes of over or under protection common to other methods of analysis, increasing electrical system reliability. |

SAFETY!! Statistics show that 5 people are injured by an electrical arc flash daily. NFPA 70E has established guidelines for arc flash assessment and OSHA and IMSA are enforcing these guidelines.

What do I do to comply with arc flash requirements?

What do I do to comply with arc flash requirements?

Be Prepared Don’t get burned!

“Arc-flash is an electric current that passes through air when insulation or isolation between electrified conductors is no longer sufficient to withstand the applied voltage. The flash is immediate, but the result of these incidents can cause severe injury including burns. Each year more than 2,000 people are treated in burn centers with severe arc-flash injuries.”

-National Fire Protection Association

Arc Flash Label Based on Completed Assessment

Generic Arc Flash Label

NFPA 70E

What Does It Mean To You?

What Does OSHA Expect From Me?

What Can You Do?

Peggy LaVaque, [email protected]

Safety and Loss Control Consultant, East and Southeast Portland Metro Area, Columbia

Gorge to The Dalles

Historically, the National Electrical Code (NEC) and other safety codes have been

primarily concerned with protection from fire, electrocution, and shock hazard—arc flash

hazards were not specifically addressed. This is now changing; the 2002 NEC contains

requirements for warning labels, and the National Fire Protection Association (NFPA)

70E—2004 and Institute of Electrical and Electronics Engineers (IEEE) 1584-2002

provide guidance on implementing appropriate safety procedures for arc flash hazards.

The ruling is straightforward. Companies are required to make arc flash hazards an

integral part of an ongoing documented safety program. The official ruling from the

Department of Labor states:

“Though OSHA does not, per se, enforce the NFPA 70E standard, OSHA considers the

NFPA Standard a recognized industry practice. The employer is required to conduct

hazard assessment in accordance with 29 CFR 1910.132(d)(l), and 1926.28(a).” The

employer is responsible to:

1. Assess the hazards in the work place

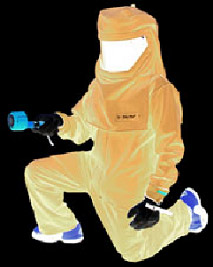

2. Select, have, and use the correct personal protective equipment (PPE)

3. Document the assessment

4. Train their staff on the hazards

“If an arc flash hazard is present, or likely to be present, then the employer must select

and require employees to use the protective apparel. Employers who conduct the

hazard/risk assessment, and select and require their employees to use protective clothing

and other PPE appropriate for the task, as stated in the NFPA 70E standard, are deemed

in compliance with the Hazard Assessment and Equipment Selection OSHA Standard.”

In short: Follow NFPA 70E to be in compliance. But even more importantly, follow the

NFPA 70E to protect employees. Don’t confuse what is needed with what is required.

What Does OSHA Expect From Me?

OSHA expects quite a bit, actually. Safety is not to be a passive, reactive policy that is

brought out after-the-fact or for show-and-tell. Reviewing some of the major requirements:

● Employers must know what their employees do. Understand that 1910.296 only

applies to power generation, transmission, and distribution installations and

related equipment. Supplementary electric generating equipment (emergency,

standby, or similar purposes) is only covered in Subpart S. OSHA 20 CFR

1910.269(a)(2)(iii) states: “The employer shall determine, through regular

supervision and through inspections conducted on at least an annual basis, that

each employee is complying with the safety-related work practices required by

this section.” OSHA would consider that tasks that are performed less often than

once a year to necessitate retraining before the performance of the work practices

involved.

● Employees must be trained in their job tasks. OSHA 29 CFR 1910.332 states:

“The training requirements contained in this section apply to employees who face

a risk of electrical shock that is not reduced to a safe level by the electrical

installation requirements.”

● OSHA 29 CFR 1910.301 through .308 basically paraphrases the National

Electrical Code (NEC).

● Selection and Use of Work Practices: OSHA 29 CFR 1910.333(a) General.

Safety-related work practices shall be employed to prevent electric shock or other

performed near or on equipment or circuits, which are or may be energized. The

specific safety-related work practices shall be consistent with the nature and

extent of the associated electrical hazards.

(1) Deenergized parts. Live parts to which an employee may be exposed shall be

deenergized before the employee works on or near them, unless the employer

can demonstrate that deenergizing introduces additional or increased hazards

or is infeasible due to equipment design or operational limitations. Live parts

that operate less than 50 volts to ground need not be deenergized if there will

be no increased exposure to electrical burns or to explosions due to electric

areas.

Note 1: Examples of increased or additional hazards include interruption of

life support equipment, deactivation of emergency alarm systems, shutdown

of hazardous location ventilation equipment, or removal of illumination for an

area.

Note 2: Examples of work that may be performed on or near energized circuit

parts because of infeasibility due to equipment design or operational

limitations include testing or electric circuits that can only be performed with

the circuit energized, and work on circuits that form an integral part of a

continuous industrial process in a chemical plant that would otherwise need to

be completely shut down in order to permit work on one circuit or piece of

equipment.

Note 3: Work on or near deenergized parts is covered by paragraph (b) of this section.

● In addition, review and consideration of 1926.416(a) {3/K} is a must.

So where should you focus your attention? It seems logical that safe work practices

should be the focus, and you should ensure that you have qualified personnel who

understand the hazards involved with the specific tasks they are required to do for their

jobs.

One of the best features of 70E is the tables, specifically Table 130.7. This will assist you

in choosing what PPE is required for standard tasks that electrical workers perform.

What Can You Do?

Get up to speed on the regulations and the NFPA Standard 70E.

The real reason we should apply the OSHA regulations and NFPA 70E is because no one

wants to see another person injured or killed. If we make decisions based on a lack of

knowledge, it can have a negative consequence on our employees’ lives and on our future.

For a copy of the NFPA 70E Standard, visit www.nfpa.org. For copes of the U.S.

Department of Labor Occupational Safety & Health Administration Standard

Interpretations, visit www.osha.gov.

Standard Interpretations: 10/18/2006 – Incorporation of NFPA 70E-2000 into OSHA

Standards, and 07/25/2003 – General Duty Clause (5(a)(1) citations on multi-employer

worksites; NFPA 70E electrical safety requirements and personal protective equipment.