Online Data Management Software

In 2006, Thermal Technologies began the successful launch of our barcoding program. This system has allowed us to streamline our processing, resulting in:

A) Quicker turnaround of reports

B) Standard CD copy

C) Development of history file of problem issues

D) Simply overall better documentation

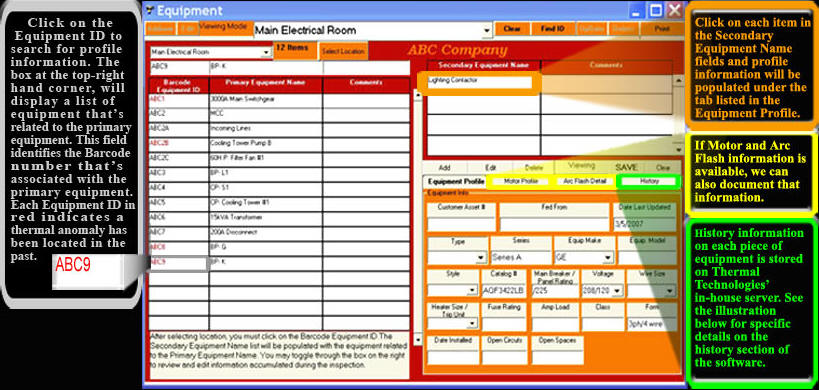

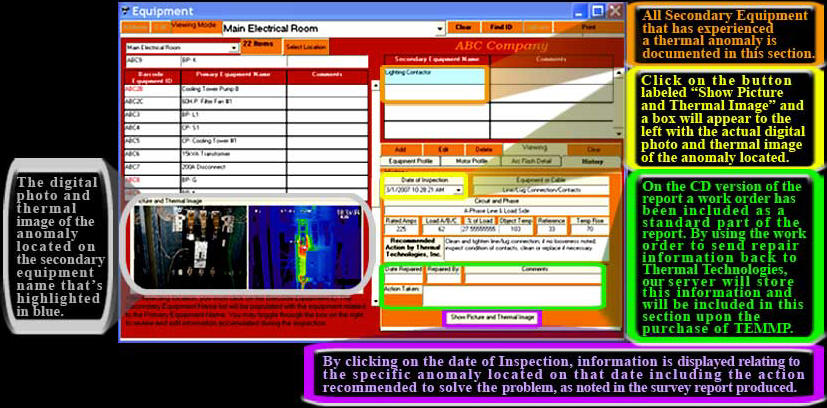

Thermal Technologies goal is to continue providing improvements to our infrared maintenance program. Our next step is to provide our customers with a complete program to manage the maintenance of your electrical distribution system. Thermal Technologies’ answer is our in-house developed software package TEMMP (Thermal Electrical Maintenance Management Program). This software is designed to give our clientele the tool to document their thermal problem areas, the repairs made to these problems and the ability to profile information about every component in their electrical distribution system.

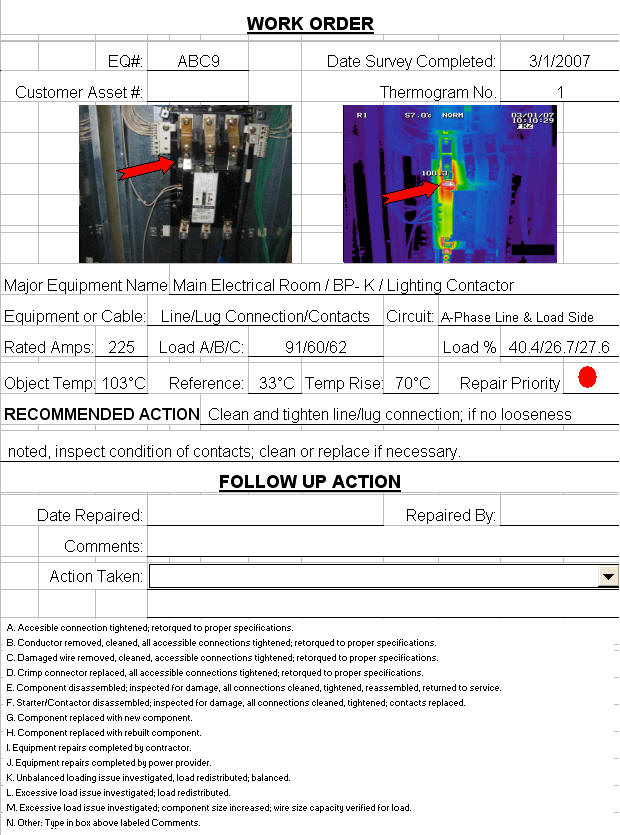

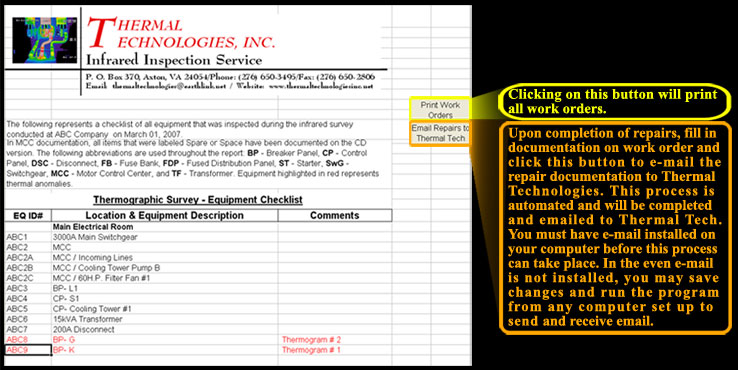

This process begins with a simple change to the CD version of our report. A standard third page for each anomaly will now be found on the CD version only. This page is a printable work order, allowing the customer to document repair actions. Your repairs can be documented within the web-based software where a complete history of problems and repairs will be stored for later review. With the TEMMP software, our clients can analyze history, record profile and motor data information, and document NFPA70E arc flash PPE requirements.

Below is an example of the NEW third page, the work order, that is available on the disks.

Work Orders/Repairs Status

Work Order/Repairs Procedure

Equipment Profile

Equipment History

Working closely with our customers has always been Thermal Technologies key to success. With the launch of our TEMMP software package, we look forward to providing the best overall thermal maintenance program available.

Since the conception of TEMMP DNA….

| 411,242 items scanned |

| 188,102individual pieces of equipment scanned and documented |

| 73,852 MCC buckets scanned and documented |

| 21,775 problems located in electrical systems in three years |

| 2,665days of infrared testing in past three years |

| 558 clients with confidence in their electrical systems |